Have you ever wondered how custom embroidery transforms a simple piece of fabric into a work of art? It’s a fascinating journey filled with creativity, precision, and craftsmanship, and we want to share all the secrets. So, let’s delve into how custom embroidery is made, from the initial design to the finished product.

Step 1: The Design Phase

The journey begins with the design phase. This is where the magic starts. Whether it’s a company logo, a piece of art, or a personalized message, the design is the blueprint for the embroidery. Designers use specialized software to create or digitize the artwork. This software translates the design into a format that embroidery machines can understand, mapping out each stitch and color.

Creating a digital design involves several key considerations:

- Detail and Complexity: The design must be simplified to ensure it can be effectively rendered with thread.

- Color Selection: The right thread colors are chosen to match the design accurately.

- Stitch Type: Various stitches (e.g., satin, fill, or run stitches) are selected to achieve the desired texture and effect.

Step 2: Selecting the Fabric

Choosing the right fabric is crucial for the success of the embroidery. Different fabrics interact differently with thread and stitches. Common choices include cotton, polyester, denim, and canvas, each offering unique characteristics. The fabric’s weight, weave, and texture affect how the final embroidery looks and feels.

Step 3: Preparing the Fabric

Once the fabric is selected, it needs to be prepared. This involves:

- Cutting: The fabric is cut to the appropriate size.

- Stabilizing: A stabilizer is added to the fabric to prevent it from stretching or moving during embroidery. Stabilizers can be temporary or permanent and are chosen based on the fabric type and the complexity of the design.

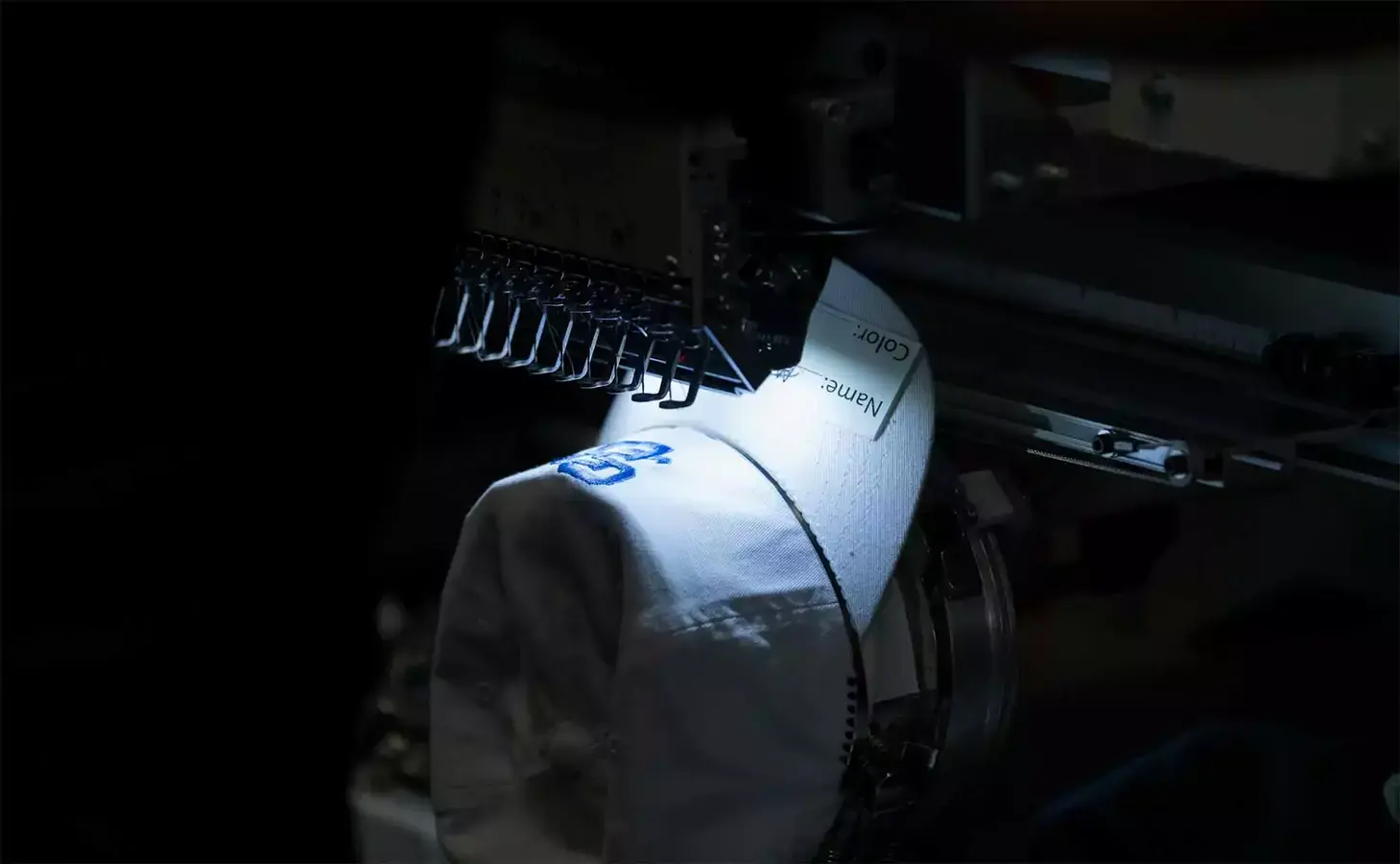

Step 4: Setting Up the Embroidery Machine

With the design digitized and the fabric prepared, it’s time to set up the embroidery machine. Modern embroidery machines are highly sophisticated and can execute intricate designs precisely. Here’s how the setup process works:

- Hooping: The fabric is placed in a hoop to keep it taut and secure during stitching.

- Threading: The machine is threaded with the appropriate colors. Some machines can hold multiple spools of thread, allowing for seamless color changes.

- Programming: The digitized design is uploaded to the machine, and settings such as stitch density, speed, and thread tension are adjusted.

Step 5: The Embroidery Process

Now, the real magic happens. The embroidery machine springs to life, following the digitized design to create the embroidery. This process involves:

- Stitching: The machine follows the programmed path, stitching the design onto the fabric. Different types of stitches are used to create various textures and effects.

- Color Changes: The machine automatically changes threads as needed for designs with multiple colors, ensuring each design section is correctly colored.

- Quality Control: Continuous monitoring throughout the stitching process ensures that the design is accurately executed that there are no issues, such as thread breaks or misalignments.

Step 6: Finishing Touches

Once the embroidery is complete, it’s time for the finishing touches. This stage includes:

- Trimming: Excess threads are cut away to give the design a clean look.

- Removing the Stabilizer: If a temporary stabilizer is used, it is removed. Permanent stabilizers remain but are trimmed to be less visible.

- Pressing: The embroidered fabric is pressed to smooth out wrinkles and set the stitches.

Step 7: Quality Inspection

Quality control is a critical part of the embroidery process. Each piece undergoes an intricate inspection to ensure it meets the highest standards. Inspectors check for:

- Stitch Quality: Ensuring that all stitches are uniform and free from defects.

- Color Accuracy: Verifying that the thread colors match the design specifications.

- Fabric Integrity: Ensure the fabric has not been damaged during embroidery.

Step 8: Packaging and Delivery

The final step in the custom embroidery process is packaging and delivery. Each piece is packed carefully to ensure it arrives in perfect condition. For businesses, this might involve bulk packaging for large orders, while individual orders are packaged with a personal touch. The goal is to present the embroidered items beautifully and securely.

The Craftsmanship Behind Custom Embroidery

Custom embroidery is more than just a mechanical process—it’s an art form that requires skill and precision. Each step, from design to finishing, involves meticulous attention to detail. The digitizing phase transforms a simple sketch into a complex pattern of stitches. The selection of fabric and threads requires an understanding of materials and color theory. Operating the embroidery machine demands technical expertise to ensure that every stitch is perfect.

Moreover, the creativity involved in custom embroidery allows for endless possibilities. Whether a simple monogram on a shirt or an intricate design on a jacket, embroidery can be tailored to fit any vision. This flexibility makes it popular for personal gifts, corporate branding, fashion, and more.

Why Quality Matters

The quality of the embroidery is paramount. High-quality embroidery stands the test of time, maintaining its appearance through wear and washing. It reflects positively on a brand, conveying professionalism and attention to detail. For individuals, quality embroidery adds a touch of personalization and luxury to everyday items.

Investing in high-quality custom embroidery ensures that your designs are beautiful, durable, and long-lasting. It’s an investment in craftsmanship and excellence, providing a final product that is truly a work of art.

A Final Word

From beginning stages to the final quality inspection, creating custom embroidery is a blend of art, technology, and craftsmanship. Each step is essential in transforming a simple fabric into a beautifully embroidered masterpiece. Whether you’re looking to create personalized gifts, enhance your brand’s image, or add unique touches to your wardrobe, understanding the intricacies of custom embroidery will help you appreciate the skill and effort involved.

Next time you admire a piece of custom embroidery, remember the detailed process behind it and the craftsmanship that brings it to life. It’s this combination of precision and creativity that makes custom embroidery a timeless and valued art form.